Offer

Polaris P® – More Than One Answer

Tailored Paper Filter Technology. One Platform. Three Paths to Performance.

Polaris P® is a next-generation platform for paper filter rod manufacturing – engineered to meet the specific needs of producers at every scale. Whether you seek full automation, balanced flexibility, or a compact entry-level solution, Polaris P® offers a tailored answer to your production goals.

Developed with efficiency, modularity, and operator ease in mind, the Polaris P® series combines high-speed performance with smart material handling and scalable architecture. Each configuration supports production of sustainable paper filters while maintaining the precision and consistency required in today’s evolving tobacco and nicotine markets – including heat-not-burn and eco-friendly applications.

-

Polaris P 780/2 AA – Fully Automated Excellence: A dual-bobbin 780 mm machine delivering continuous, unattended production with robotic bobbin preparation and changeover. Perfect for high-volume, industrial-scale manufacturing.

-

Polaris P 1200/2 MA – Smart Semi-Automation: A dual-bobbin 1200 mm configuration blending automatic changeovers with manual preparation for optimized performance and flexibility.

-

Polaris P 1200/1 MM – Minimal Cost, Maximum Robustness: A single-bobbin 1200 mm machine for manual operations – compact, affordable, and ideal for smaller runs or niche segments.

All Polaris P® systems deliver cutting speeds up to 5000 cuts per minute, recipe-based changeovers, and intuitive HMI control, ensuring seamless production and reliable quality.

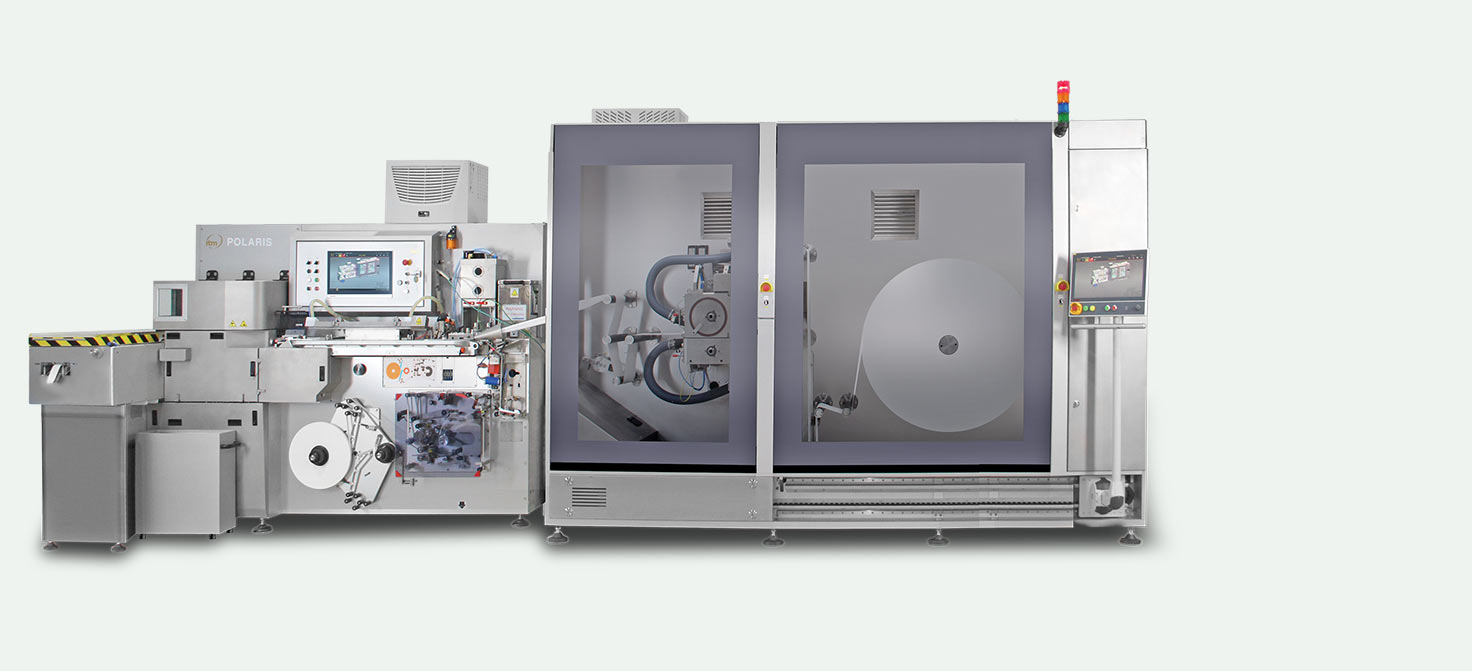

Polaris P 780/2 AA

Fully Automated Paper Filter Rod Maker – Maximum Efficiency with Robotic Precision

Polaris P 780/2 AA is the most advanced configuration in the Polaris P range, tailored for high-output environments that demand full automation, precision, and minimal operator workload. Designed to work with two 780 mm bobbins, it delivers an entirely automated process—from bobbin preparation to splicing and changeover. A robotic arm supports the bobbin loading process, ensuring speed, safety, and reliability. As a result, operators are free to focus entirely on supervision and quality assurance rather than machine operation.

- Fully automated bobbin handling, including preparation, robotic loading, splicing, and changeover – allowing uninterrupted production without operator intervention.

- Production speed up to 5000 cuts per minute, ensuring high throughput and consistency.

- Precise pressure drop (PD) adjustment via HMI, accurate to 0.01 mm, even during operation.

- Integrated splicing unit delivers smooth transitions between bobbins without stopping the machine.

- Advanced glue systems compatible with PVA and Hot Melt, including flexible glue pattern selection.

- User-friendly HMI interface for real-time control, diagnostics, and fast brand changes via recipe memory.

- Compact, “All on Board” design – minimizing installation time, reducing maintenance complexity and reduced layout comparable to acetate filter maker machine

- Perfect for industrial-scale manufacturing sites focused on high OEE, efficiency, and labor optimization.

Polaris P 1200/2 MA

Semi-Automated Paper Filter Rod Maker – Balance of Performance and Control

Polaris P 1200/2 MA bridges the gap between full automation and manual operation. This model works with two 1200 mm bobbins and features automatic bobbin splicing, while the bobbin preparation remains manual. It’s the ideal solution for manufacturers who seek to optimize production with smart automation, while retaining some level of manual oversight for operational flexibility.

- Semi-automatic configuration – bobbin changeover is automatic, but initial preparation is carried out manually.

- Precise pressure drop (PD) adjustment via HMI, accurate to 0.01 mm, even during operation.

- Two-bobbin system with 1200 mm capacity enables extended production cycles and reduced operator intervention.

- Output speed up to 5000 cuts per minute, delivering high production efficiency.

- Flexible glue pattern selection, including seam and anchoring glue lines.

- Modular crimping and rod-making units allow simple future upgrades and customization.

- Fast format and length changeovers, supported by intuitive recipe management system.

- Suited for medium to large-scale manufacturers seeking high output and adaptability without full automation costs

Polaris P 1200/1 MM

Manual Paper Filter Maker – Compact, Efficient and Budget-Friendly

The Polaris P 1200/1 MM is a cost-effective yet highly efficient solution for producing paper filter rods. Designed specifically for small to mid-size manufacturers, it offers a high degree of process control while minimizing investment costs. The machine integrates both the crimper and rod maker into a single compact module. Bobbin preparation and material changeover are performed manually, ensuring operational simplicity and affordability.

- Single 1200 mm bobbin operation – manual preparation and bobbin change.

- Stable production speed up to 5000 cuts/min, ensuring consistent output.

- Precise pressure drop (PD) adjustment via HMI, accurate to 0.01 mm, even during operation.

- Easy access to key components such as cutting units, rollers, and glue application systems.

- Ideal for manufacturers entering the paper filter segment or targeting niche production needs.

- Compact design with “All on Board” architecture, enabling minimal installation time and low maintenance effort.